Systèmes de trempe par induction

En cas de trempe par des systèmes de trempe par induction, il s’agit dans la plupart des cas d’un chauffage partiel des composants. La transformation structurelle (austénitisation) résulte du principe de l’induction. Les avantages sont les suivants : courts temps de chauffe, déformation minimale, chauffage partiel, apport de chaleur homogène, faible calaminage, raccordement facile à des lignes de production entièrement automatiques.

Arbres de transmission, crémaillères, arbres d’induit, composants à rotation symétrique.

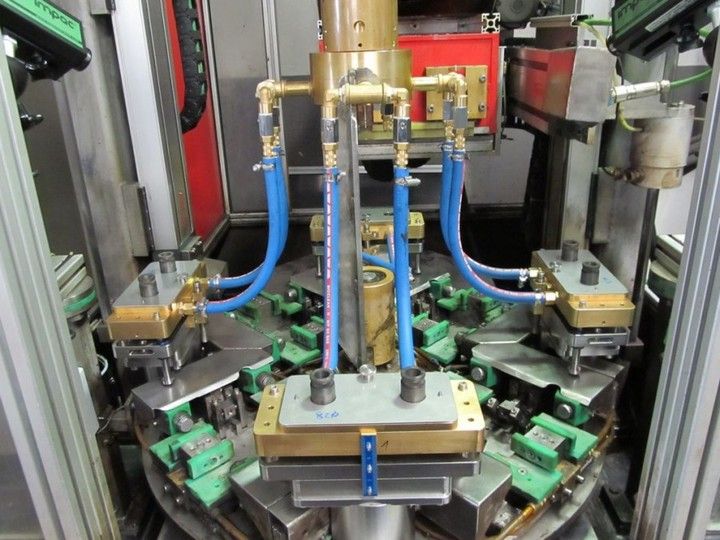

Machine universelle pour petites et moyennes longueurs de composants à rotation symétrique. Un changement des dispositifs permet également l’usinage de composants asymétriques.

Brasage / trempe simultanés de 3 à 5 pièces à usiner (également possible sous gaz protecteur).

Idéal pour le chauffage inductif, le soudage et l'assemblage pour les constructions de moteurs électriques. Le châssis peut être en aluminium ou en fonte.

4 axes CNC-Hardening / Heating Machine