Inductive Hardening Technology

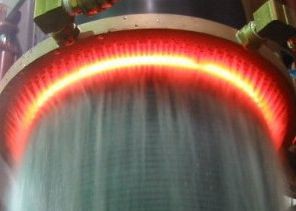

During hardening by induction is usually around, limited to the surface hardening of a component, wherein structural transformation (austenitizing) is caused by the principle of induction. The induction-hardened component is most Stress-relieved immediately after the hardening process. This is achieved by "tempering" the component. A distinction is made in principle for the induction hardening between different methods volume / in-feed -- Stop/ rotation/ stop / and volume feeding method. Basic requirement for induction is a minimum carbon content of the hardened steel.

Benefits of induction hardening:

- Short hardening times

- Hardening of small part zones

- Nearly scale free parts

- Reduced distortion

- Repeatable Hardening process

- Repeatable Hardening results

We will be pleased to contact you on this subject. We look forward to hearing from you!

Our most important products within the inductive hardening technology:

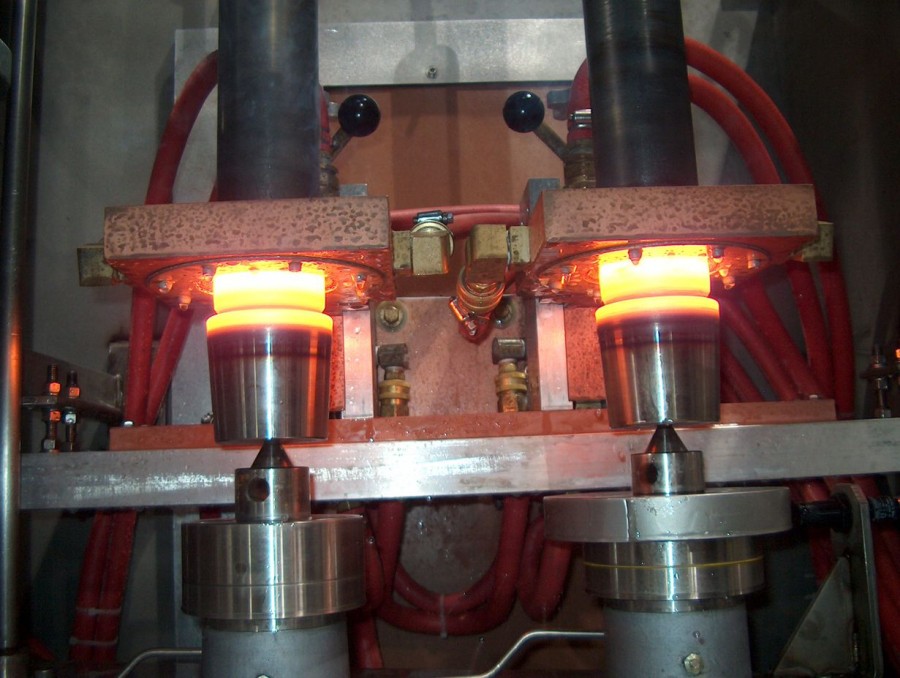

Ideal for Inductive heating, soldering and joining for electric motor constructions. The chassis can be made of aluminium or cast iron.

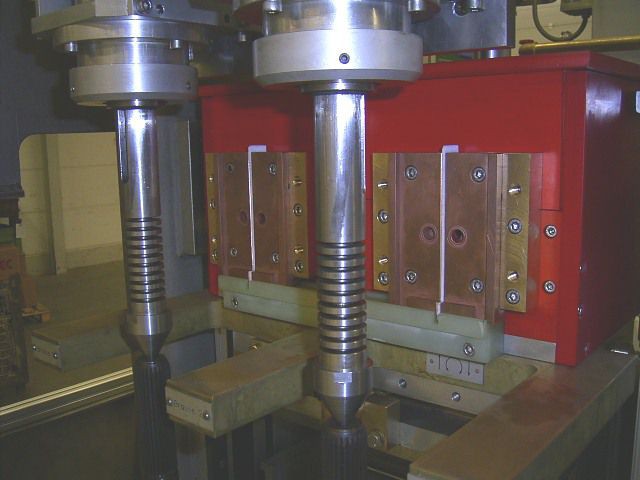

Universal machine for small to medium component lengths, different parts are possible due to device changes.

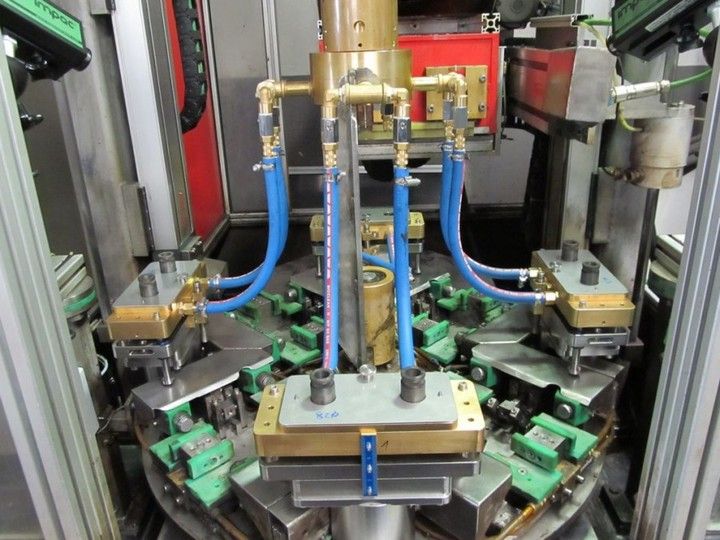

Hardening / brazing of 3-5 components at the same time (also with inert gas)