Induction Brazing System

Product description

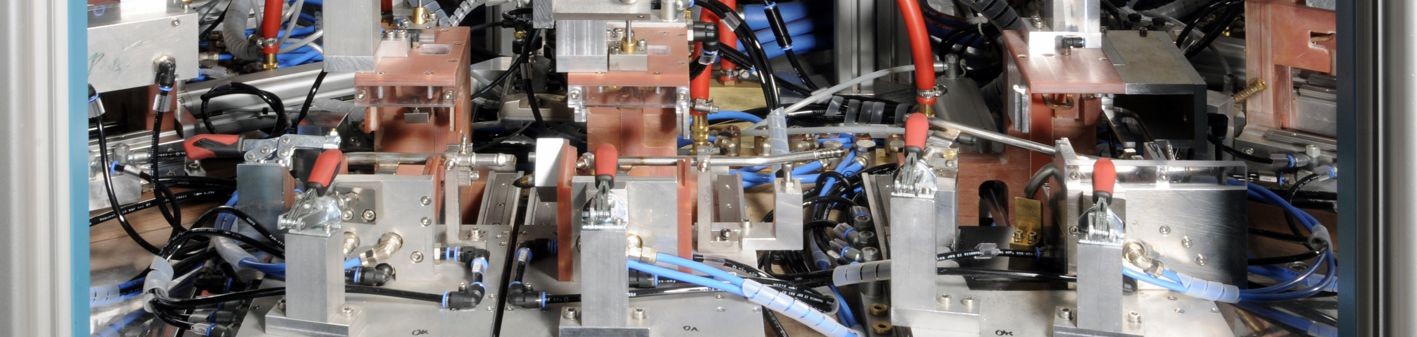

The Induction Brazing System has an integrated automatic small parts feed system and an integrated automatic marking system. Brazing takes place under inert gas atmosphere or normal atmosphere and can be conducted with and without flux.

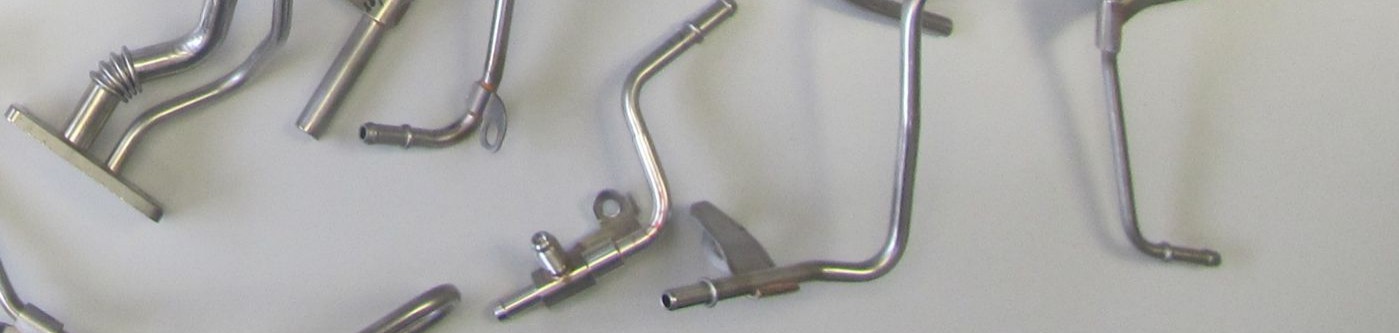

There is a great variance of applications like for example bended tubes, straight tubes and material like stainless steel, steel, copper, brass or aluminium which can be brazed with induction.

The Brazing System has an integrated automatic wire feed system whereas automatic brazing with the wire feed system and temperature control are possible.

Program flow is storable for a lot of fixtures / applications with the aid of xxx. The system includes an internal cooling water circuit sized to meet maximum for power supply and inductors. Through diverse power supplies in selectable form multiple brazings are possible. Multiple brazings have short cycle times.

Moreover, large number of units are possible with complex brazing tasks are possible. The machine can be used with different brazing fixtures with different parts and is therefore highly flexible.

All electrical cabinet components are easily accessible from the front side of the cabinet. Integrated HMI simplifies operation and maintenance.

Maximum up time through quick changeovers to new process data and other components. The Induction Brazing System can be easily integrated in automated systems.

For further information please do not hesitate to contact us.We look forward to receiving your call under +49 6272 9217-500

All specifications subject to change without notice.

Technical details

- HF/MF - IGBT Power supply

- Power 10-50 kW

- Frequency range 10-300kHz

- Siemens S7-300 controls or customer preferred controls

- Integrated PLC for process status and process data

- Industrial PC operator panel

- High quantities with complex brazing tasks (more than 10 brazings per assembly group)

- Small cycle times through multiple brazing

- Inert gas control / inert gas monitoring

Options:

- Remote control of the system

- Task lighting

- Wide range of power supplies

- Identification system for brazing fixtures

- Temperature control

- Quantity counter for gas / air / power

- Data storage system with Raid and USV

- Hand Barcode / Datamatrix Reader

- Marking system like laser, dot peen

- Automatic wire feed system

- Mobile lift table for brazing fixtures

- On-site technical support

- Training